Energy management systems have no secrets for us, on the contrary, we are true experts. IT, electronics, electricity, automation, they are all part of what we do. With our own developed hardware and software, we help you optimise the energy efficiency of your injection moulding company to make room for growth and development. And all that at a fast service and independent of third parties. Too good to be true? We don’t think so!

Don’t be fooled

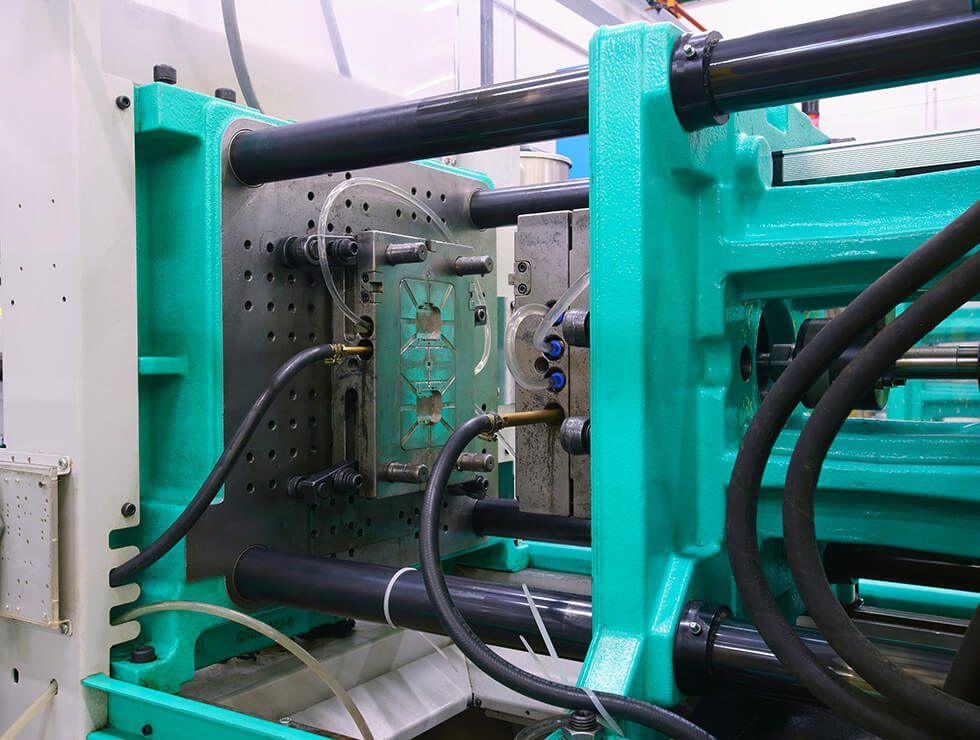

An in-house production process is not to be underestimated, and neither is the power of optimal energy efficiency. When it comes to energy, as an injection moulding companies you often only look at the cheapest price per kWh. This may or may not surprise you, but it doesn’t give the full picture. It is therefore very valuable to have data on what the exact energy cost per product output is. In this way, your production process can be adjusted to this, which in turn means nothing less than working as energy-efficiently as possible and thus being able to pay better prices. Not too shabby right?!

Get to know your energy consumption

The Internet of Things’, does it ring a bell? Wikipedia defines it as ‘The set of devices (“things”) that are in contact with other devices or systems via internet connections and thus exchange data’. Think of all the devices that together create a “smart home”. It may sound all hip and trendy, but it comes with certain challenges that cannot be underestimated: a complicated configuration, limited programming, and moreover, it often doesn’t show the co-relation between the various machines at all.

Not to worry, BePowered to the rescue! We provide your injection moulding company with insights into the efficiency level based on KPIs. This data is crucial for optimising your machine park because it is only with this data that the correct payback period for further investments can be calculated. Our weapon of choice? Our financial calculator! The insights into costs not only help you make sharper offers, but the operational manager also has a reference figure that can be optimised.

All data nicely gathered

Using a gateway, we can connect any type of data or protocol to the BePowered Cloud platform. Another cloud you think. Don’t worry, let us explain. We configure any type of equipment on the gateway. The entered data is visualised on a dashboard on the internet, so that once it has been processed, you can monitor it, detect it, be alarmed if necessary or be reported.

BePowered offers you a clear and structured overview with all the necessary data about the electricity network of your machine park and office. This allows you to keep the energy accounting and monitoring of your injection moulding company running smoothly. Simple, isn’t it?

BePowered, a one-stop-shop

In other words, we can fully tailor the BePowered Cloud platform to your needs. With its real-time insights about the energy efficiency of your machine park, you are always kept up to date in our Cloud platform. This way you have access to the acquired data anytime, anywhere. Our software works on both old and new devices and is completely brand independent. It can even be integrated with other energy management systems. We took care of everything!